We've independently reviewed this article to make sure it's as accurate as we can make it.

To find out more about our article creation and review process, check out our editorial guidelines.

Are you wondering how much weight can plywood hold?

Whether you’re planning a home renovation or looking for a temporary solution for a sagging mattress, understanding the load-bearing capacity of your materials is crucial.

In this article, you’ll find a calculator to work out how much weight any given plywood would hold.

Plywood strength mostly depends on its thickness, number of layers, wood type, and grain direction. The increased thickness means plywood supports much more weight, as it can redistribute the stress away from the center.

Read on to learn more about this!

How Strong Is Plywood?

As mentioned before, plywood strength mostly depends on its thickness, so that’s how we’ll present this answer. In general, for a 3ft span of plywood:

| Plywood Thickness | Strength (Max Pressure) |

| 3/8″ | 22psf |

| 1/2″ | 35psf |

| 3/4″ | 80psf |

| 1″ | 164psf |

As you can see, a 1/2″ plywood can support up to 35 pounds per square foot. But doubling that thickness to 1″ of plywood supports up to 164 pounds per square foot.

Thick plywood can distribute weight more evenly, which reduces the amount of stress on any single point. This allows plywood to support heavier loads.

A quarter-inch thick plywood could barely support 5 pounds of weight, so we didn’t include it above.

Now, please bear in mind these are example values. This is assuming:

- An example plywood span of 3 feet

- The lowest amount of layers (3 ply for 3/8” & 1/2”,4 ply for 3/4”, 5 ply for 1”)

- Plywood is fixed at both sides, with the wood grain running parallel to the span.

Keep reading for our free plywood weight calculator below!

Finding The Weight That Plywood Can Hold

As a Civil Engineer, this topic was close to my heart – so I’ve put together a simple calculator that anyone can use to estimate their plywood strength.

Please bear in mind that this calculator assumes:

- Your plywood is fixed at both ends. In other words, it’s nailed down and secured.

- The strength axis is parallel to the grain. This simply means that the grain of the wood runs across the span which is taking the load.

- No load factors applied (i.e. construction imperfections, material imperfections, potential snow-load, or weakening with time are all not taken into account).

- This calculator should be used to give ball-park estimates only, and not for structural calculations.

Simply input your plywood type and span to get an approximate load capacity.

Sources

- Design values taken from the 2005 edition of the AF&PA American Wood Council’s Allowable Stress Deign (ASD)/LRFD Manual for Engineered Wood Construction. Find them online here.

- Span ratings to plywood thickness taken from Engineered Wood Association tables.

Plywood Strength Factors

Before you dive into throwing down weight onto your plywood, it’s important to understand the different factors in its strength.

The type of plywood you have massively changes the amount of weight it can have.

There are 4 key factors which make up a plywood’s strength:

#1 Thickness

As with any material – the thicker it is, the stronger it becomes.

Compare the strength of a piece of paper to a ½” thick piece of wood. The difference is huge, but the only real change is the thickness.

This is just as true for plywood. In fact, even more so because of how plywood is made.

In general, the thinnest plywood available is around a ¼” thick. This isn’t useful for much, and can only hold up to 10 lbs or so.

Try not to exceed the weight capacity limit, otherwise, plywood may buckle, crack, or break, and you may get hurt.

The most common plywoods are 1/2-3/4” thick. These sizes are for anything from quick DIY projects to home structural uses.

The thickest pieces of plywood are only 1-1/4” thick. Slim in the grand scheme of things, this plywood is strong enough to be used in industrial building projects.

For general purposes, even just 3/4” is super strong. Typically it would be the framework/edges of the plywood which would break before the board itself gives way.

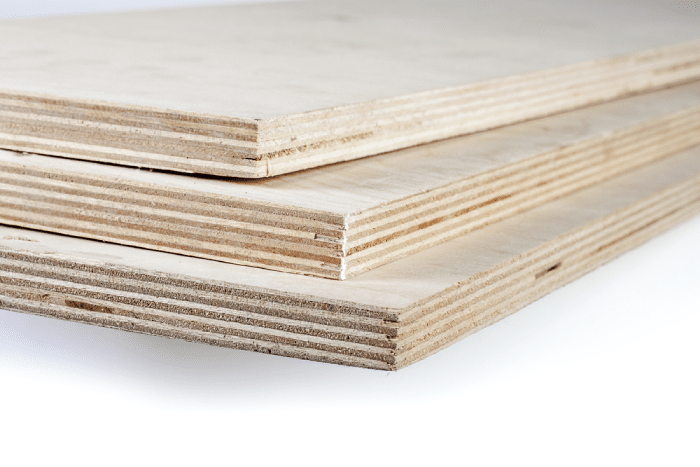

#2 Layers

The reason why thickness matters so much with plywood is due to the layers.

For that reason, the number of layers is specified in a plywood’s name by ‘Ply’. 3-ply means 3 layers, 4-ply is 4 layers, etc.

Being made from thin layers glued together, more layers greatly increase the strength of plywood.

Anything from 3-4 layers is ‘shop-grade’ – cheap plywood for small DIY uses. Going up to 4-7 layers means the plywood can be used for furniture – like kitchen cabinets, or even flooring. Anything above 7 layers is incredibly strong, but starts to limit functionality.

Typically, you’ll be choosing between 3-5 ply from your local store. Each layer can add around 5psf of load capacity, so pick accordingly.

#3 Wood Species

Any wood material changes depending on the type of wood you’re using.

With plywood, it boils down to hardwoods vs softwoods.

In short, softwood is cheaper but doesn’t have nearly as much strength. It’s more useful as cladding and can be covered in exterior glue so that it doesn’t absorb any moisture – retaining its strength for a long time.

#4 Grain Direction

An often overlooked factor is the direction in which the wood grain is running in.

Any piece of plywood that you buy should have the grain of the wood (the lines that run through the timber) running down its longest length.

Any wood is strongest in the direction of the grain. Plywood, for example, gets its strength from crossing the grain between the layers perpendicularly.

Think about it like a bunch of interconnected plastic straws. When the straws are slotted together end to end, they’re strongest. When placed side by side, they fall apart.

Wood is the same – it’s the grain that helps transfer the load to the supports.

Not my best example, but hopefully it gives you an idea!

Analysis

As anyone who knows me will tell you – I can’t resist a spreadsheet.

In this case, I’ve done a quick analysis to look at how important plywood thickness and layers really are.

For each of the APA plywood listings, I’ve calculated an approximate total loading capacity for a 3-ft wide plywood span.

As you can see, the thickness increases linearly with strength, and adding a layer provides a jump of around 25-50 lbs of total load capacity.

Conclusion

I hope this article has helped answer any questions about how much weight plywood can hold.

Maybe even a little too much of an answer…

If this content has helped you, please consider supporting us by checking out our related articles below! For any feedback, please get in touch via our contact page: I’d love to hear from you.

Best of luck with your projects, and have a great day.