We've independently reviewed this article to make sure it's as accurate as we can make it.

To find out more about our article creation and review process, check out our editorial guidelines.

Feeling confused about the differences between MDO vs marine plywood?

You’re not alone! Understanding their differences can be a bit tricky. But the good news is that with the help of this article, you’ll be able to tell both materials apart in no time.

When choosing between MDO vs marine plywood, it’s important to consider your needs. MDO is usually lighter, more affordable, and has a smoother finish that makes it perfect for painting. Marine ply, on the other hand, is more flexible and a bit more water-resistant, but can be pricier.

Ready to learn more? Let’s go!

MDO vs Marine Plywood

It’s clear that MDO and marine ply were originally designed for specific uses. As such, their key features are distinct. But as DIY’ers have found more and more uses for them, the overlap of usage areas has grown bigger.

Let’s look at what makes them both stand out.

#1 Price

Compared to standard ply, both MDO and marine are more expensive. But with higher quality woods, glues, and manufacturing processes, it’s understandable.

Of the two, marine plywood is more expensive and, in some cases, can be up to twice the price of MDO.

This is one of the major reasons MDO has become so popular. Unless you really need marine ply’s superior features, MDO is a good choice.

#2 Weight

Another important feature to consider when choosing between MDO vs marine plywood is weight.

Plywood weights can vary considerably depending on the woods used. But in general, a similar sheet of MDO is lighter than its marine equivalent.

This makes MDO the preferred choice for weight-sensitive projects.

#3 Finish

Because of the resin layer in MDO, it gives a very smooth finish and accepts paint easily. Meaning that, when all else is equal, the paint will last longer on an MDO board. It was, after all, originally intended for sign painters.

The smooth finish on MDO means it’s a great choice for paintwork. You usually do not need to spend a lot of extra time preparing the surface. For most applications, fine sanding will be enough.

Marine ply typically comes with a veneer finish. If you’re after that traditional wooden look, it can be a good option. However, a lot of manufacturers have different veneers, and you may need to shop around to find the one you want.

#4 Flex

The fiber resin in MDO makes the boards less bendable than their marine ply equivalent.

So, if you’re looking for projects that involve a lot of shaping, then marine ply might be the better option. As a key component to a lot of wooden boats, marine ply was designed to be molded.

#5 Strength

Both MDO and marine ply are strong. And considerably stronger than the standard plywood intended for internal use. But if strength is your primary concern, then marine comes out on top.

The combination of top-grade woods (to be classed as marine ply, the plies must be a minimum of B grade), no internal voids, and the exacting manufacturing standards, make marine ply extra strong.

#6 Water Resistance

Neither is technically waterproof. Water-resistant is probably a better term. But even here, there are differences.

Because they originally designed marine ply to spend a lot of its life in water, it’s slightly more resistant to moisture than MDO. In particular, the fact that no internal gaps exist in the layers means it’s harder for water to get between them.

With marine ply, delamination should never be an issue.

But the differences usually aren’t that important for most standard uses. As long as you properly coat the ply, and take care when treating the edges, then both MDO and marine will stand for many years and take the worst that weather can throw at them.

Indeed, even in boat building, there are a lot of vessels that make extensive use of MDO.

#7 Typical Uses

MDO is used for all types of signage, exterior paneling, fascia, and soffits. A lot of commercial users like its smooth surface and excellent strength for building concrete forms.

And it’s often used indoors for bathrooms or kitchens. A lot of hobby and commercial furniture makers like MDO for its strength and durability.

Marine ply is, not surprisingly, often used in boat building. The top quality, resistance to delamination, and extra strength make it perfect for all marine applications including hulls, docks, and jetties.

A lot of artisans swear that nothing but marine ply is good enough, and if cost is not a consideration, they may be right.

FAQ

If you haven’t made up your mind yet about whether to choose MDO or marine ply for your project, you might want to keep reading.

In this section, we’ll answer the most common questions about both materials. This way, you can make an informed decision.

What is MDO?

Medium-density overlay or MDO refers to the special layers of fiber between each layer of plywood. Normal-grade plywood is not protected against humidity and other harsh conditions that MDO can withstand.

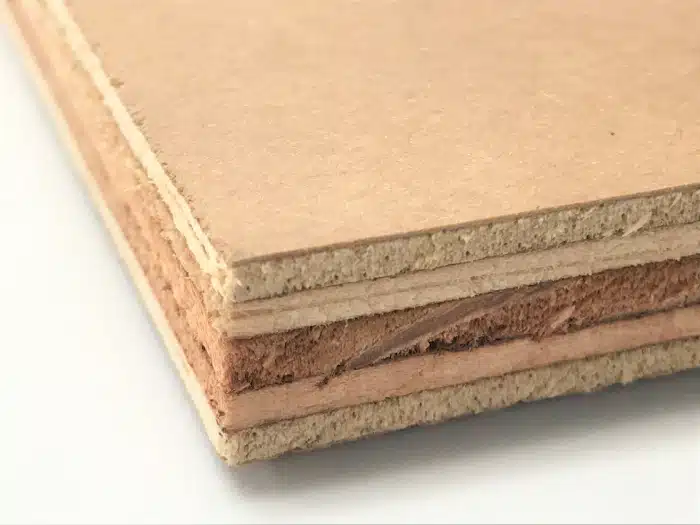

MDO ply uses a thin layer of fiber resin to bond each layer together. Manufacturers also finish the outside surfaces (sometimes both, sometimes only one depending on the grade) with this resin. When painted, this makes MDO much stronger and more durable than standard plywood, and suitable for all sorts of outdoor applications.

First established around fifty years ago, they originally made MDO for sign makers. People wanted a weatherproof board that would be easy to paint onto and last a long time. This is why some still refer to MDO as “signboard”.

Often confused with MDF (medium-density fiberboard), MDO is a true plywood that is stronger, and more durable, whereas MDF is made from layers of wood fibers. Like other true plywood, MDO is made from thin wood layers peeled from the tree.

What Is Marine Plywood?

Marine grade, on the other hand, is a type of plywood that manufacturers make to a specified high standard. Each layer is hardwood and selected for containing few defects. But what makes marine ply is the manufacturing process.

The best quality boards come with a standardized mark from a recognized authority. Each layer uses a waterproof glue and there are no core gaps, which helps prevent moisture from getting in between the plies.

Finally, the bonding is conducted under strict pressure and heat requirements.

Aren’t MDO and Marine Ply Basically the Same?

The short answer is, yes and no. Some people consider MDO as a form of lower-grade marine ply, and they often rank it as such.

The differences are in the quality of wood used and the type of bond. Marine ply has fewer defects and absolutely no internal gaps. Also, while you can only paint MDO, you can paint and seal marine plywood (if it’s kiln-dried).

Are MDO and Marine Plywood Waterproof?

Actually, no. Contrary to popular belief, neither marine ply nor MDO are waterproof. They both use waterproof glues, and MDO usually has a resin coating, which makes them water-resistant.

But they do not treat the wood or add any rot-inhibiting chemicals. If exposed to moisture over time, both boards will absorb water.

That is why it is extremely important to have a good finish. No matter which type of ply you use, make sure you coat the wood correctly and are particularly careful with the cuts and edges.

The reason for the waterproof glues is to stop delamination. If moisture gets in between the layers, it means that they won’t separate. Something that’s pretty useful if you’ve used it to build your boat or stand out in the rain.

Conclusion

That’s it. We’ve covered marine plywood vs MDO – differences explained and compared. Now you know what they are, what they’re best at, and what to use them for.

If you need the absolute best of the best, where quality is the only criterion, then marine ply can’t be beaten. The wood grades, the manufacturing, and the lack of internal voids make marine ply the premium product.

But if you’re looking for something almost as good, except with a better price point, you can’t beat MDO.

Now it’s time to make your choice and get cracking on your next project. Whichever you choose, you can’t really go wrong. Good luck and happy building.

— Craig.