We've independently reviewed this article to make sure it's as accurate as we can make it.

To find out more about our article creation and review process, check out our editorial guidelines.

Is your swamp cooler squeaking?

Don’t worry, this is a common issue. In fact, thousands of people struggle with it every day.

Luckily, you’ve come to the right place to get it fixed.

If your swamp cooler is squeaking, chances are there’s a loose fan belt, the bearings or wheels need to be lubricated, or you have a damaged fan cage shaft. A faulty fan motor or water pump could also explain the issue.

Read on to learn how to solve the problem!

5 Reasons Why Your Swamp Cooler Is Squeaking

A swamp cooler works through a process of heat transfer, where hot dry air is cooled by evaporating cool water. The heat is condensed, and then the water is evaporated. The end product is cool air.

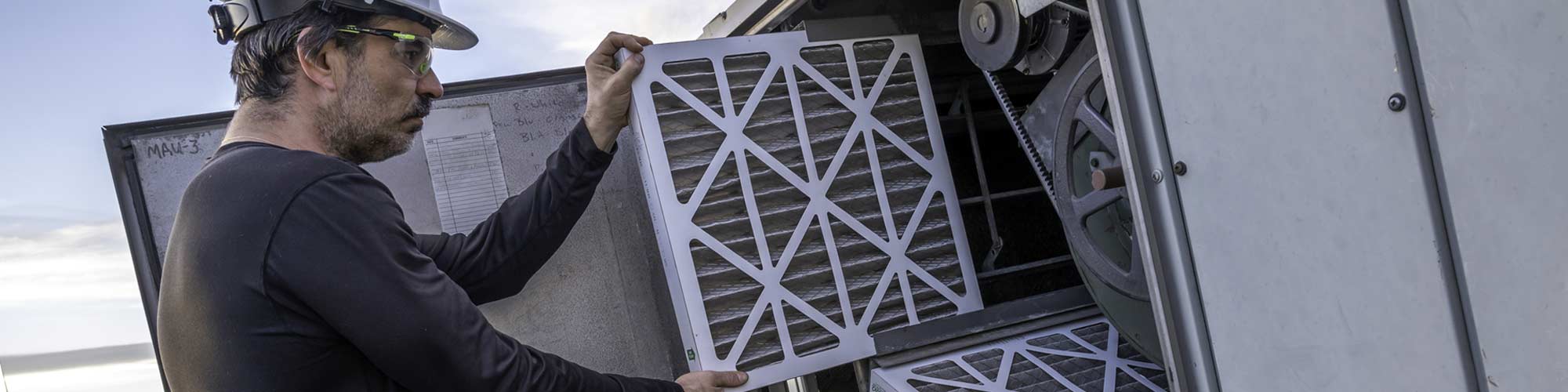

For a place that’s typically dry and hot, swamp coolers are ideal compared to air conditioners. However, there is basic maintenance that needs to be done for a swamp cooler, especially since it does involve electricity, water, and several moving parts.

The moving parts that can cause the squeaking sounds are:

#1 Check The Fan Belt

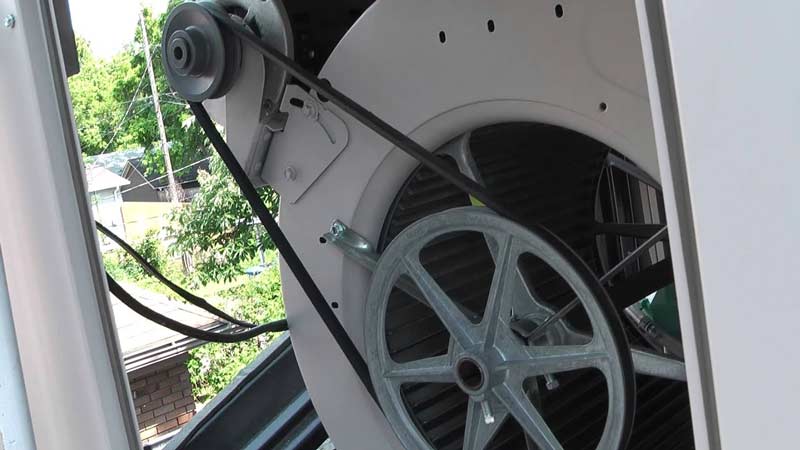

Your swamp cooler relies on a fan (or blower cage) to rotate and pull natural air into the unit for the evaporative process to start. To do this, the fan is rotated by a motor. The motor rotates the fan by rotating a motor pulley that rotates a belt that rotates a fan (or blower cage) pulley.

When looking at a swamp cooler schematic, you can always tell the motor pulley from the fan pulley based on size. The motor pulley is always smaller. The reason is that the motor pulley rotates at a higher rate but produces lower torque.

That lower torque rotates the larger fan pulley, increasing the output energy enough to rotate the larger fan. However, for that fan to rotate the energy created by the motor needs to be translated to it, in this case, via a belt.

People often ask me what the belt has to do with squeaking. Well, if a belt is loose or slipping, you’ll very likely hear squeaking (or squealing).

The fix is to make sure the belt is properly tensioned in accordance with your manufacturer’s recommendations.

Another issue with the belt may be damage or just normal wear and tear. You should inspect the condition of the belt and replace it if necessary.

You may be wondering if you need to lubricate the belt like you can with a squeaking belt on a car. Normally, you don’t have to. If your belt is tensioned right, there shouldn’t be any more squeaking because of the belt.

Lubricating belts for cars and lawnmowers usually help prevent them from squeaking if they’re slipping and prevent them from drying out. The belt for your swamp cooler shouldn’t have that same issue if it’s properly tensioned. If it’s worn out, replacing it is typically the best option.

That all being said, a little silicone lubrication won’t hurt. In fact, it’s useful for the preservation of the belt in times when your cooler won’t be run for extended periods of time.

#2 The Fan Cage Bearings Squeaking

As noted, your swamp cooler’s fan rotates thanks to a motor-driven belt. That belt travels on both motor and fan cage pulleys. Those pulleys each ride on a shaft.

So, if the belt isn’t the source of the squeaking, it could very well becoming from another rotational element; the fan cage shaft and its bearings.

If you were wondering if the motor has a shaft, too, you’d be correct. However, the motor’s shaft is very small and less likely to make the kind of squeaking associated with the bearings for the fan cage.

Why?

Really it comes to weight. The fan cage is bigger than the motor. To support it and the pulley rotating it, there needs to be a shaft for it to rotate on.

For that shaft to remain in place while it rotates, it has to rest on a bearing on each side of the fan cage. To reduce friction, those bearings need lubrication.

Now, a lot of newer swamp coolers have sealed bearings that don’t require routine maintenance and lubrication. However, older models do. The squeaking you hear may very well be dry bearings in need of lubrication.

So, how do you lubricate the bearings for your swamp cooler?

Well, each bearing should have a cap. All you need to do is pop the caps off and put a couple of drops of bearing oil in and replace the caps. The oil should be free of detergent, so don’t use motor oil. There’s already pre-made products out there you can use at very little cost.

#3 Damaged Fan Cage Shaft

If you’ve identified that the fan cage bearings needed lubrication but still have a squeak, you may need to inspect your fan cage shaft.

You’re more likely to have more of an odd vibration than a squeak if there’s a problem with the shaft, but still, a damaged shaft is a damaged shaft so the noises one makes can always vary.

Like other parts for swamp coolers, replacement shafts aren’t hard to find. However, if you don’t feel comfortable replacing it on your own, it’s always good to call a technician, especially if you’re concerned that isn’t the only issue with your cooler.

#4 The Squeaky Wheel Gets the Grease

If you’re dealing with a swamp cooler that hasn’t been run in a while, and now you’re dealing with an annoying squeaking sound, it’s always a good idea to look for any loose parts on your cooler that need tightening.

This is very true in the case of portable swamp coolers, especially if you move them from room to room often, or had them stored in say a garage for a while.

It’s also advised to inspect whole-house swamp coolers for loose parts, as well. If there are outside units, they’re exposed to the weather all the time, even when not used.

So, you have to take into account not just the impact of temperatures when it comes to expansion and contraction, but also wind and storms.

Just as you want to make sure the parts that need tightening and lubrication are taken care of, you also want to check out the parts you may not think about.

Like the wheels.

Yes, even the wheels on your portable swamp cooler can start squeaking.

Now wait a minute, why would the wheels squeak if it’s not moving?

Ah, but if there was an unusual vibration within the cooler, it may be moving the cooler just enough to make the squeaky wheels, well, squeak.

Is it likely the reason? Probably not. The grander point is, if you’ve got to do some detective work to track down the cause of an issue, you might as well check out all the other stuff you can while you’re at it.

#5 Fan Motor and Water Pump

Last but not least, if you’re still dealing with squeaking noises and check out the fan belt, the bearings, the shaft, and other possibly loose items in and on your cooler, it’s probably time to consider an issue with either the fan motor or water pump.

Normally, if you had an issue with either one of these, your swamp cooler wouldn’t be operating normally. You’d first notice a lack of cooler air than normal, along with the squeaking.

But then again, the squeaking could be the first indication of a bigger problem getting ready to happen with a motor or pump. With a motor, it may be starting to seize up. With the pump, it may be an issue starting to develop with the impeller.

Either way, you may have to replace them. To be sure, you can always consult a technician or service center.

Conclusion

A squeaking swamp cooler can be an annoying thing, even if it seems to be working normally outside that terrible sound.

And almost all the time, the squeak is related to a rotational element on your cooler’s fan side, whether it’s the belt, bearings, or a shaft problem.

That being said, that squeaking sound could also be an early indicator of a bigger problem. Regardless, diagnosing the problem takes inspecting your cooler, making corrections or replacements where needed, or even calling a technician if a bigger issue is identified and needs addressing.

Thank you so much for reading! Please take a look at our other related articles below.

Good luck!