After your lawn mower, your next most important piece of equipment for lawn maintenance is probably your strimmer (string trimmer). And like your mower, if it’s not working properly (in this case constantly cutting or stalling out), life can get a bit frustrating.

So, the first question should be why is your strimmer cutting out? This is usually followed by, “Is there an easy fix?”

Well, let’s take a look at some of the reasons why your strimmer might be acting up in this fashion and some of the quick fix options you can utilize to overcome this annoying obstacle without having to tear your equipment apart, repair it, or replace it entirely.

1. The Fuel Filter

When it comes to a strimmer cutting or stalling out, the first two things you’re going to want to investigate are the two things essential for it to run in the first place. The two things are fuel and air.

You could also say that without a spark you’re going to have issues, too, but before the spark, you’re going to want to ensure your fuel/air ratio is mixed as designed. If it isn’t, the spark isn’t going to matter.

What’s meant by that is too much or too little fuel or too much or too little air will completely throw off your combustion cycle. This can result in non-starts, flooding, incomplete starts, and eventually stalling out.

So, let’s take a look at the first half of that all-important mixture: fuel.

And when it comes to your strimmer’s fuel system, the easiest thing to check right off the bat is the condition of your fuel filter.

Sounds simple enough. The good news is: it is simple!

No, that wasn’t yelling at you. That was genuine happiness for you.

Why?

Well, the fuel filter is something easy to check. It’s inexpensive to replace. And it’s something you should be inspecting and/or replacing on a regular basis based on your manufacturer’s recommendations.

So, go ahead and inspect that filter. If it’s all clogged up and nasty looking, well, you have evidence it’s doing its job by preventing bad stuff from contaminating the fuel and making it into the engine. The bad news is it did its job so well it’s now preventing the right amount of good fuel from getting into the engine for combustion.

The task here is to get a new filter and replace the old one. Once done, and maybe with a fresh tank of gas, fire up the strimmer and see if that’s eliminated the problem.

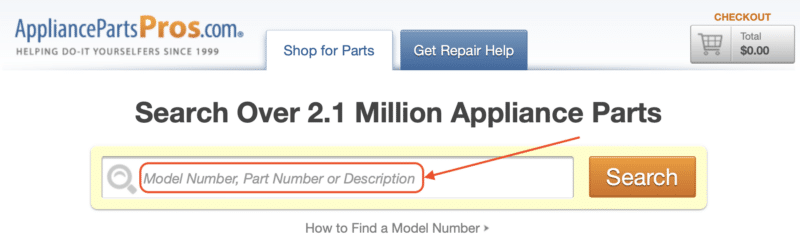

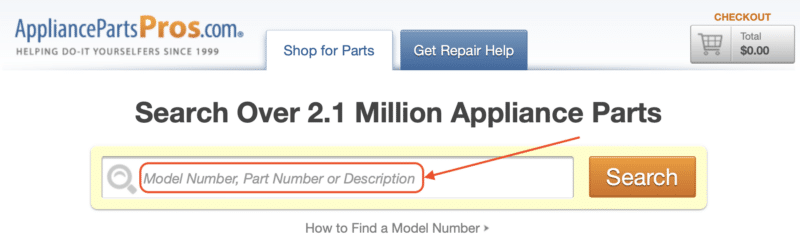

If you want to get any replacement part – or see how much one would cost – click to enter your model number in the search bar below. Our partners at AppliancePartsPros stock almost every part with free guides on how to install them.

If you’re still experiencing engine cut-out, move on to checking…

2. The Air Filter

That’s right, the other half in that all-important mixture needed for combustion. If your fuel filter is good but you’re still having issues starting or keeping your strimmer running, it’s time to check the air filter.

This process is much like the fuel filter, and like the fuel filter, the air filter is meant to provide clean air to the engine while filtering out as many contaminants as possible. If it’s old and dirty, it’s done its job, too, but it may be preventing the right amount of air that needs to pass through into the combustion chamber from, well, passing through.

Like the fuel filter, the air filter is meant to be replaced as part of regular maintenance per your manufacturer’s recommendations. If it looks dirty or worse, just replace it.

3. Spark Plug

Okay, now that you’ve replaced your fuel and air filters, let’s check and make sure you’re getting spark. You’re going to want to do two things here.

Inspect the coil wire

Inspect the spark plug

Before pulling the plug, inspect the coil wire that’s attached to it. Check for any slits, cuts, abrasions, etc, that may be preventing the spark plug from operating as intended.

If the wire looks good, inspect the plug itself. Besides looking for damage, also check for oil build-up, gunk, etc., that may interfere with the amount of spark needed for continuous combustion.

Sometimes you can clean the plug but often it’s just as easy to replace it.

4. Spark Arrestor

Speaking of sparks, it wouldn’t be a bad idea to inspect your spark arrestor. This is a common problem with an easy fix that a lot of people don’t consider.

Basically, the spark arrestor is a screen that arrests sparks. Or, to put it another way, it prevents sparks produced within the engine from coming out.

However, like air and fuel filters, the spark arrestor can also get clogged up with dirt and other debris that limits its function and can lead to an engine cutting out.

If your spark arrestor is dirty, clean it with a wire brush and reinstall it.

5. Gaskets

Yes, if you haven’t noticed, it’s time to move on to the stuff you normally inspect and replace. Now it’s time to investigate items that aren’t common issues but, if they have problems, will lead to poor engine performance and stalls.

The first was the spark arrestor. The next is your strimmer’s gaskets. Gaskets are designed to create a tight seal where two pieces meet to form a connection. If you have damaged gaskets, you can have everything from leaks to improper intake air.

Obviously, a visual inspection will often let you know if a gasket is leaking. Think of a car. When your water pump starts to go, you’ll usually see a leak under your car. Those kinds of pumps are designed with weep holes to let you know the pump is dying before the gasket fails. If the gasket fails, you’ll have fluid all under your car.

A strimmer doesn’t have that level of courtesy. But you can still usually tell when a gasket is leaking. Look for fuel and oil streaks where they shouldn’t be.

Ah, but what about a bad air seal?

This kind of gasket is typically found below a carburetor. If it’s damaged, it will suck in too much air and mess up that fuel-to-air ratio mentioned above. To inspect it and replace it, you’ll need to remove the carburetor.

Speaking of the carburetor, will get back to that in just a second. First, though, check…

6. The Fuel Lines

Another visual inspection but one that should be done to ensure you’re not losing fuel prior to it arriving in the combustion chamber. Replace damaged lines as necessary.

7. Carburetor

Yes, time to talk about the carburetor. Why does it come last? Well, although a damaged or worn carburetor can be a common problem that leads to strimmers cutting out, it’s also the problem that takes the most time to repair or replace or may involve a technician’s help with all the other issues addressed.

When dealing with the fuel-to-air ratio, to this point, you’ve inspected and possibly replaced all the easier issues that may impact said ratio. If all of those other troubleshooting fixes haven’t helped, it’s time to consider the carburetor.

Simply put, the carburetor is responsible for maintaining the appropriate fuel/air ratio. Over time, a carburetor can get dirt and oil residue built up within it. Cleaning a carburetor isn’t uncommon or difficult. Get some carburetor cleaner and follow your manufacturer’s guidance.

However, cleaning doesn’t always work, especially on older strimmers. In cases like this, you usually have three options. One is to purchase a carburetor repair/rebuild kit. If you’re really into hands-on repair, this might be the weekend project for you.

The second option is to just purchase a completely new carburetor.

The last option is to take the strimmer to a technician or service center for repair or replacement. Yes, it’ll cost more money but if you’re not looking to be a strimmer mechanic for a few hours, it might be your best option. Also, you might get a decent warranty for the work.

Conclusion

Like a lawn mower, a strimmer that’s not functioning the way it should is pretty irritating. When it’s shutting down or cutting out as soon as you start it, well, it’s not just irritating. It’s keeping you from getting the work you have to get done, done.

Thankfully, the issue can often be boiled down to either a problem with the fuel or air sides of the strimmer. With those potential issues come some quick troubleshooting tips and easy fixes that should get your strimmer running the way it was designed.

Remember, though, you should always be ready to ask for help if the easy fixes don’t work. In cases like that, it’s not bad to admit the fix isn’t easy but you did what you could and it’s time to call a technician.